Metallurgical overhead cranes are Weihua's superior products, which are mainly used in steel mills, aluminum plants and other metallurgical industries.

According to different processes, there are different types of metallurgical bridge cranes, which usually include bridge cranes used in a series of production processes such as casting cranes and handling cranes. It is mainly used in the metallurgical industry for the handling of ladles, steel pipes, steel plates, coils and scrap steel.

Metallurgical overhead cranes include: ladle cranes, teeming cranes, chaging cranes, tundish cranes, foundry cranes, slab handing cranes, steel coil handing cranes.

The slings of metallurgical bridge cranes can be various types such as hooks, grab buckets, electromagnetic spreaders, and clips.

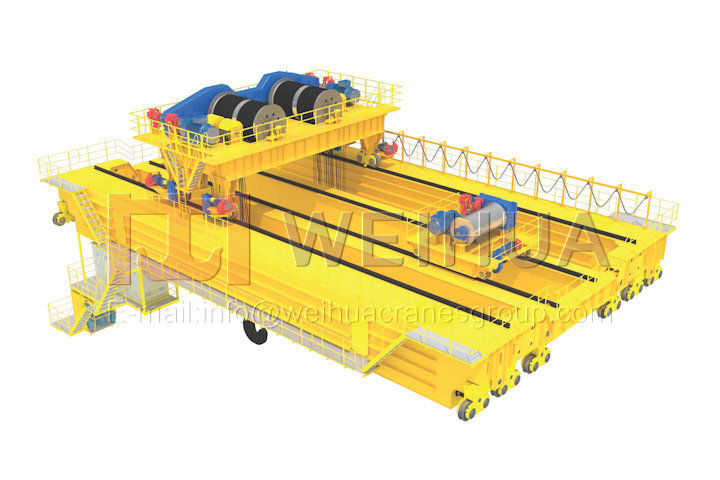

Overhead cranes in the metallurgical industry can be divided into double-girder double-rail, four-beam four-rail, four-beam six-rail and other types in the overall structure. The first two are generally used for bridge cranes of medium and large tonnage, while the four-girder and six-rail are used for bridge cranes of extra-large tonnage.

Our overhead cranes for the metallurgical industry have a lifting capacity of up to 550 tons.

Weihua's 2021 sales will be $2.28 billion, with steel mill cranes accounting for 36% of total sales. In the field of metallurgical overhead cranes, we have rich design experience and industry-leading auxiliary design systems. Our technical department has 1000 people and can meet any of your technical needs. You can communicate and improve the crane design through technical meetings, conduct video factory inspections at any time, or send personnel to our factory to supervise production.

Weihua bridge cranes have been the No. 1 sales volume in China for 14 consecutive years, and we have 34 years of rich experience in the crane industry.

No matter what type of overhead crane you need, we can meet your needs. You can consult our experts and we will customize the design according to your needs.