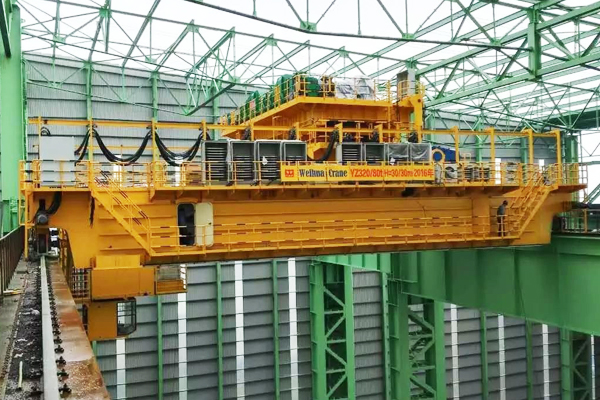

Casting crane is a special bridge crane in the process of steel making, It usually includes: Ladle crane, Teeming crane, Charging crane and Tundish Crane. It is mainly used in metal smelting workshop to lift and handle hot molten metal.

Foundry cranes are usually divided into double-girder double-track, four-girder four-track and four-girder six-track structure, of which the double-girder and double-track form is generally used for small tonnage bridge cranes below 160 tons; 100~320 tons can choose four-girder and four-track main casting cranes. If it is a large tonnage of more than 320 tons, it is recommended that you choose a crane structure with four beams and six rails.

Foundry cranes work continuously in harsh environments such as high temperature, high dust and harmful gases. Compared with general overhead cranes, they have particularly high requirements for safety, reliability and stability. Whether it is the main girder, sub-girder or electrical room, our cranes have taken heat insulation and radiation protection measures, and have carried out redundant design of electrical equipment. In addition, we are also equipped with intelligent safety monitoring System, electrical anti-sway technology and advanced electrical control technology, it can not only record every operation of the crane, but also can accurately locate, realize semi-automatic or fully automatic control. These various considerations are all to ensure the safe operation of the crane with smooth, continuous high performance.

Our large monolithic structure annealing makes cranes more resilient, our submerged arc automatic welding and modular production make crane welds more even and firm, these advanced manufacturing processes are all designed to increase your productivity and safety.

As a leading crane manufacturer in China with 34 years of experience in the crane industry, Weihua Crane has been adhering to the concept of safety first and efficiency first from the very beginning. Thanks to the trust of our customers, we have produced and sold 1 million sets of crane-related equipment in 34 years, and accumulated a lot of manufacturing experience in the industry. ArcelorMittal, the world's largest steel mill, chose to use our products and chose to cooperate with us again in 2021, signing an order of 110 million. In addition, we also serve many steel plants in China and around the world. As the world's largest professional material handling equipment manufacturer and service provider, our crane products are used in more than 130 countries and regions around the world.

Whether it is a steel mill or other industries, no matter what type of crane you need, you can consult our experts and we will provide you with the best crane solution.