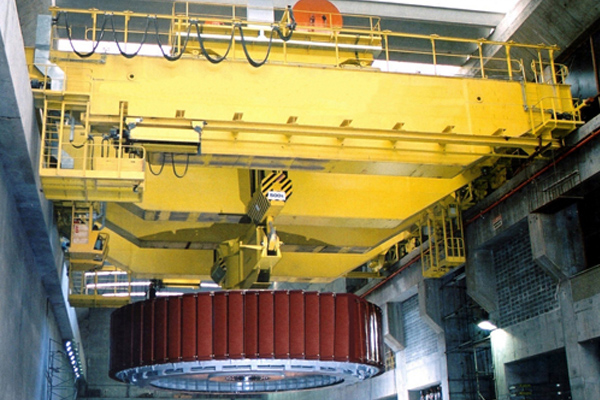

The 100-ton overhead crane is a top-running crane, usually a double-girder structure, which usually carries out material handling work in workshops, warehouses and livestock farms.

100 ton overhead crane, carrying extremely heavy and bulky loads in different workshops. In order to optimize your productivity and save your space and plant construction costs to support the cranes, our overhead cranes usually have the advantages of their own light weight, low crane height and small left and right limits.

It is widely used in heavy machinery workshops, steel warehouses, foundries, steel mills, lumber mills and scrap plants, etc. In extreme environments, it needs to lift and move heavy objects smoothly and safely. There are various configurations and designs depending on the application. Whatever your industry, we can provide you with a perfect crane system.

Depending on the application, overhead crane systems can vary widely in size, operation and complexity. You can customize different components to increase the capacity and performance of the crane, usually divided into three areas: the girder, the trolley, the main hoisting mechanism.

Our 100 ton overhead cranes come in many types. They are usually lifted in indoor workshops. Job levels are usually A5 and A6.

Our overhead cranes have been sold for 14 consecutive years in China. With 34 years of rich industry experience, we can provide you with the safe, stable and most cost-effective overhead cranes according to your different needs and uses.

We provide customized services for a full range of over 100 ton overhead cranes.You can choose according to your needs, or you can consult our experts, we can provide you with the best solution for 100 Ton Overhead Crane.