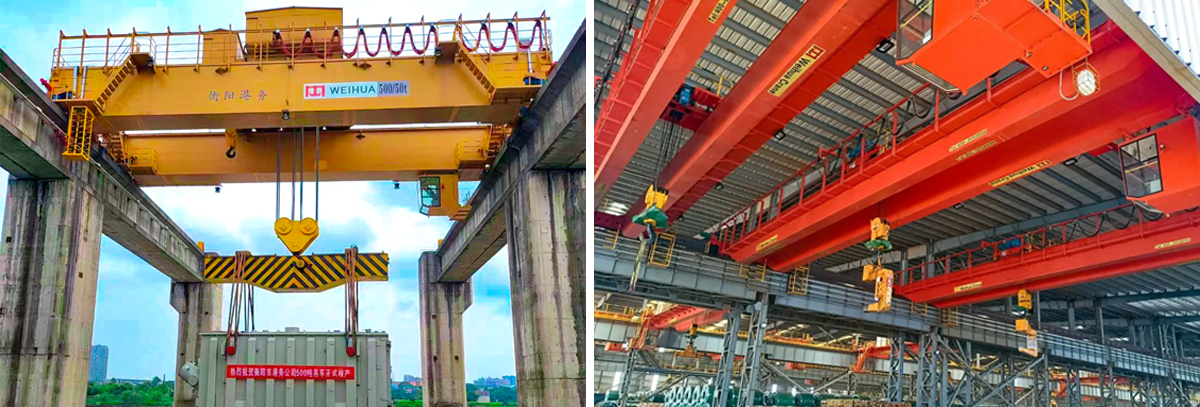

Capacity:50 Ton;60 Ton;75 Ton;80 Ton;100 Ton;150Ton;200 Ton;250 Ton;300 Ton;320 Ton;350 Ton;400 Ton;450 Ton;500 Ton;550 Ton;

Work duty: A5、A6、A7、A8

Span: customized according to customer needs

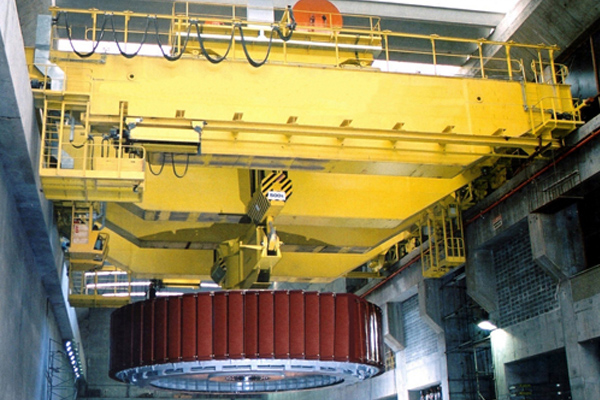

Application: The double trolley overhead crane can be used at power plant, metallurgy plant, steel plant, workshop, warehouse, papermaking, shipbuilding, etc.

WEIHUA Designed for hard use, heavy duty overhead crane is a powerful piece of machinery found in steel mills, foundries, heavy machine shops, chemical plants and warehouses. It usually comes in double girder construction. The heavy duty crane supplied by weihua can lift a large amount of weight, usually going up to 550 tons. It features sturdy strucrture, great durability, excellent safety and reasonable cost.

Industrial Applications Of Heavy Duty Overhead Cranes

heavy duty Workshop Overhead Cranes

Weihua Bridge cranes can be used in heavy workshops and warehouses to lift various loads or materials.

Steel Mill heavy duty Cranes

WEIHUA Steel plant cranes are heavy duty overhead cranes used in steel manufacturing companies for steel industry solutions. WEIHUA Crane has the professional knowledge and technology to help you perform the arduous and dangerous lifting tasks required by the steel industry. We work with you to provide equipment to lift heavy and hazardous materials throughout your operations, from handling iron ore and recycling steel to pouring molten iron and forming products in rolling mills. Technical and service team of WEIHUA Crane are experts at all stages of steel manufacturing; we are constantly striving to help you produce more steel.

You can choose according to your needs, or you can consult our experts, we can provide you with the best solution for Heavy Duty Overhead Crane.