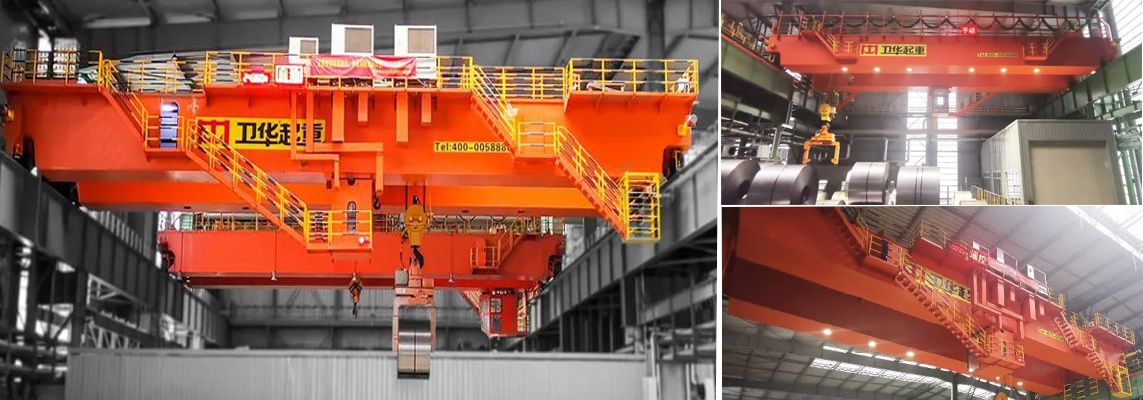

Coil handling cranes mainly handle metal bars, plates and coils during processing. It is an overhead crane usually used in steel mills and machinery manufacturing plants. This crane transports steel or coils from one production line to one The production line is shipped to another production line. It can be used both indoors and outdoors, and in most cases it is usually used in production and manufacturing workshops. Depending on the type of material to be handled, our coil handling cranes can be customized to suit your needs.

This kind of crane has high requirements for work efficiency. It needs to carry out fast and long-distance handling work, so in order to shorten its working cycle, we use a special hook, which can handle up to 80 tons of plates, pipes, coils, etc. material. In addition, we are also equipped with intelligent functions, including anti-sway control system, advanced electrical control technology and overload protection, to ensure accurate positioning and fast and stable operation of the crane, thereby shortening the handling time, reducing the wear and tear of the crane, and greatly extending the crane's life. Longevity, increase the productivity of your business.

We can provide you with accessories for any steel product and spreaders in different sizes according to your needs. You can consult our experts and we will customize a fast, stable and precise steel coil handling overhead crane for you.