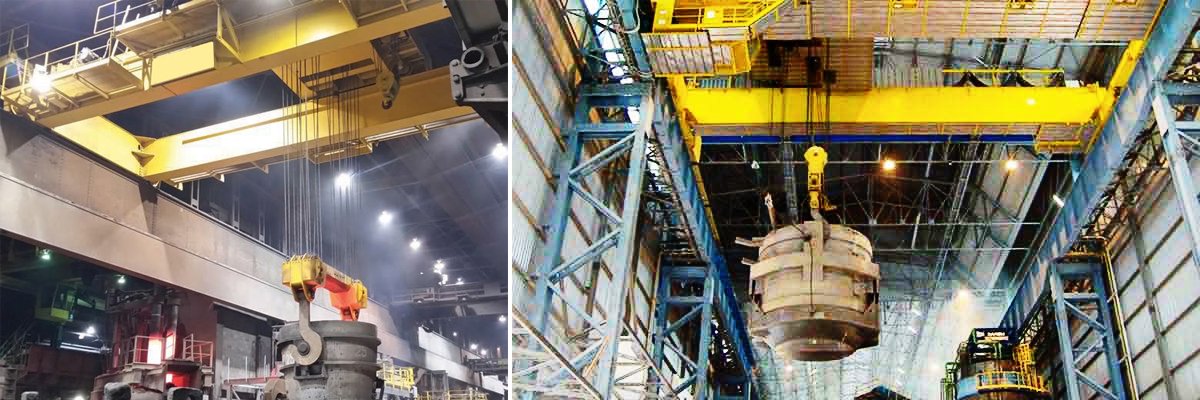

Tundish cranes are usually equipped with hooks on which lifting related equipment suitable for tundishes can be connected. It is mainly used for handling ladle containing molten steel slag.

As a ladle handling crane used in steel mills, its requirements are very high. It not only has to operate in harsh environments such as high temperature and dust, but also in special circumstances, if the continuous casting machine fails, the tundish crane must It can satisfy the ability to lift a large amount of molten steel, or even the whole package of molten steel.

Its design must meet the requirements of international standards, because the tundish crane is efficient, uninterrupted and safe in continuous use.

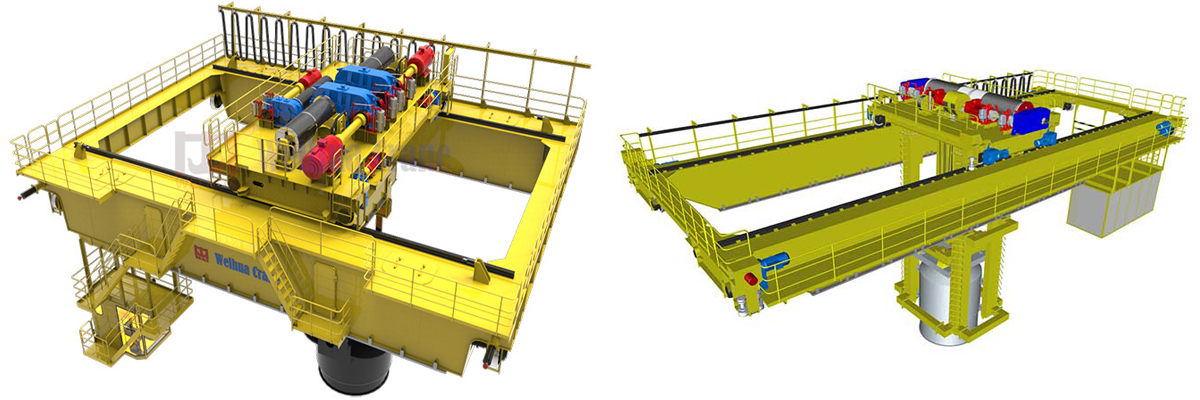

The structure of the tundish crane is generally a double-girder structure. In order to meet special needs, a three-beam bridge structure is sometimes used. Its basic working level is generally A6.

For a tundish crane, its lifting capacity depends on the capacity of the tundish. In order to ensure continuous and stable operation, the capacity of the tundish is generally 20% to 40% of the capacity of the ladle. Conventionally, the lifting capacity of tundish cranes is less than 160 tons. Due to different needs, generally such cranes are often tailor-made.

To address safety concerns without reducing productivity, our tundish cranes feature overload protection and emergency stop systems as well as derailment brackets and end limit switches, features that come standard on tundish cranes.

Our crane safety monitoring system records every crane operation. The electrical anti-sway technology can realize the precise positioning of the crane, and the advanced electrical control technology can realize the automatic and semi-automatic control of the crane. These intelligent advanced functions can not only improve the safety of crane operation, but also greatly improve the work efficiency of the crane.

All components of our mechanical and electrical equipment are carefully designed and can be adjusted, lubricated, inspected, maintained and repaired, with an emphasis on quick replacement of faulty or worn parts rather than repairs.

We have advanced steel mill crane technology and large-scale manufacturing level. In one of the industries, we have 34 years of experience in R&D, production and service. We have our crane equipment in more than 130 countries and regions around the world, so no matter what you need What type of steel mill casting cranes, we can provide you with customized services according to your needs.

You can choose according to your needs, or you can consult our experts, we can provide you with the best solution for Tundish Crane.